"Changing lenses" is a thing of the past, "2.0 electric optical zoom" has arrived

Shenzhen JEET Technology Co., Ltd. has successfully developed an electric optical zoom endoscope, which is a revolutionary breakthrough in the industrial endoscope industry.

Industrial endoscopes are widely used in aerospace, automobile manufacturing and other fields, such as inspecting aircraft engine blades. The internal structure of the combustion chamber is relatively complex. During use, it is often necessary to replace lenses with different depths of field such as near focus, medium focus, and far focus. Traditional endoscopes can only solve this detection problem by changing the lens or replacing the pipeline. In order to solve the global technical problem of zoom, JEET Technology has conducted years of painstaking research on zoom lenses. It not only realizes the manual zoom function of small-diameter products, but now also achieves a breakthrough in electric optical zoom, achieving a disruptive technological innovation in the development history of industrial endoscopes.

In daily industrial inspections, inspectors’ requirements for endoscopes have evolved from the initial need to view, take pictures, and videotape, to now the mainstream three-dimensional measurement endoscopes to measure defects and dimensions, and even require a zoom function. JEET's in-depth study of the "electric optical zoom" technology is also based on the customer's suggestion that "the depth of field of endoscopes is currently fixed, and small probe endoscopes are all fixed-focus endoscopes. They want to achieve "long focus" at the same time. "Medium focus" and "close focus" can only be achieved by changing the lens or the traditional method of replacing the pipeline system. Is there any way to directly adjust the depth of field? " This requirement.

Through many surveys, we found that many industrial endoscope customer groups are "making do" in actual working conditions. Because there is no better choice, they can only be forced to accept the existing solution: changing the lens or replacing the pipeline. system. Especially when inspecting precision equipment, the inspected object will have both near and far focus detection requirements. Customers can only take out the pipeline multiple times, change the lens or pipeline system, and repeatedly inspect the same hole position, which greatly affects the detection efficiency and Detection accuracy.

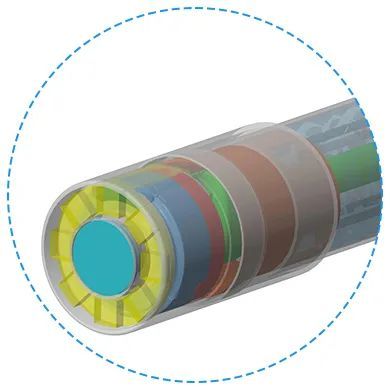

As an advanced manufacturer of endoscopes in China, JEET has established a lens research and development team to break the current situation that the depth of field of the lens can only be "fixed focus" and not "zoomed". It is working on the "electric optical zoom" technology to achieve adjustable focal length and depth of field. The range can cover 2mm~∞, and the zoom response is ≤20ms. After years of R&D and testing, the research team lived up to their expectations and finally broke the tradition and developed a revolutionary "automatic optical focus lens". At the same time, they announced that "changing lenses" is a thing of the past, and the era of 2.0 electric optical zoom has arrived. ! It breaks the traditional situation that the detection needs of different focal lengths can only be met by changing lenses or pipeline systems.

The practical application significance of "automatic optical zoom lens" in non-destructive testing:

① The depth of field can be adjusted through optical zoom to achieve multi-focus detection. Whether it is a small defect in the near focus or the search direction in the far focus, it can be clearly seen at a glance;

② High cost performance, one endoscope can have multiple depths of field at the same time, and there is no need to equip multiple lenses, which greatly saves user procurement costs;

③ Avoid secondary accidents, such as the lens not being tightened and accidentally falling into the cavity of the object being inspected, or the lens being broken due to accidental dropping, increasing maintenance costs, etc.;

④ The operation is more convenient and faster, which can avoid lens damage caused by frequent lens replacement, such as lens oil leakage, etc.

As we all know, the lens is the core of the endoscope, and JEET has mastered advanced technologies such as interchangeable lenses, manual optical focus lenses, and automatic optical focus lenses that lead the industry. In the future, we will continue to increase investment in scientific research and vigorously promote the technology of "automatic optical focus lenses". We believe that this technology will be widely used in aerospace, precision casting, automobile manufacturing and other fields.